Current location:

Links:

-

* Aerospace and defense Understanding the Dimensions of a 6303-2RS Bearing A Comprehensive Guide 4. Non-locating Bearings (Free Direction) These bearings consist of a cage that holds the balls in place, allowing them to rotate freely within the inner and outer rings. The deep groove design enables the bearing to accommodate both radial and axial loads, providing excellent balance and stability. The use of high-quality steel balls ensures durability, resilience, and reduced friction, leading to increased efficiency and longevity. Both the LM11949 and LM11910 share a common thread of reliability and robustness

- Speed Limitations: In some high-speed applications, spherical roller bearings may have limitations compared to other bearing types. Factors such as centrifugal forces and cage design can impact their suitability for certain high-speed machinery. However, without specific context, the true meaning of 6005 ZZ remains open to interpretation. It serves as a reminder of the versatility and power of symbolic language, and how a few digits and characters can spark endless curiosity and speculation. In essence, 6005 ZZ is a testament to the human capacity for imagination and problem-solving, inviting us to explore the depths of our cognitive abilities. Features of the 6210 C3 Bearing Furthermore, Timken deep groove ball bearings are available in a variety of sizes and configurations to meet the specific needs of different applications

lm11949 lm11910. They are designed to withstand harsh operating conditions, with robust protection features like current limiting and thermal shutdown, ensuring safe operation and extended device life. Their compact package sizes also contribute to their popularity, allowing for easy integration into complex circuit designs without compromising on performance or space constraints. In conclusion, the use of tapered roller bearings is rooted in their ability to effectively manage heavy loads, handle combined loads, provide self-alignment, and offer flexibility in maintenance. Their design features, along with their versatility and adaptability, make them indispensable in numerous industries, from automotive to aerospace, construction, and beyond. Understanding why and how to utilize these bearings optimally is crucial for maximizing system efficiency, reliability, and longevity. 4. Easy to install and maintain These bearings are relatively easy to install and require minimal maintenance, reducing downtime and maintenance costs. Cultural Diversity The 6206 Z bearing belongs to the deep groove ball bearing family, a widely used class due to their versatility and durability. The '6206' part of the name indicates its size according to the International Organization for Standardization (ISO) standards. It signifies that the bearing has an inner diameter of 30mm, an outer diameter of 62mm, and a width of 17mm.

lm11949 lm11910. They are designed to withstand harsh operating conditions, with robust protection features like current limiting and thermal shutdown, ensuring safe operation and extended device life. Their compact package sizes also contribute to their popularity, allowing for easy integration into complex circuit designs without compromising on performance or space constraints. In conclusion, the use of tapered roller bearings is rooted in their ability to effectively manage heavy loads, handle combined loads, provide self-alignment, and offer flexibility in maintenance. Their design features, along with their versatility and adaptability, make them indispensable in numerous industries, from automotive to aerospace, construction, and beyond. Understanding why and how to utilize these bearings optimally is crucial for maximizing system efficiency, reliability, and longevity. 4. Easy to install and maintain These bearings are relatively easy to install and require minimal maintenance, reducing downtime and maintenance costs. Cultural Diversity The 6206 Z bearing belongs to the deep groove ball bearing family, a widely used class due to their versatility and durability. The '6206' part of the name indicates its size according to the International Organization for Standardization (ISO) standards. It signifies that the bearing has an inner diameter of 30mm, an outer diameter of 62mm, and a width of 17mm. The ID taper ratio, another critical aspect, determines the bearing's load distribution and performance

Bearing, NJ, is known for its annual cultural events that bring the community together

Bearing, NJ, is known for its annual cultural events that bring the community together bearing nj 206. The Bearing Seafood Festival, held every summer, features fresh local seafood, live music, and a variety of family-friendly activities. The Bearing Winter Festival, held in February, celebrates the winter season with a parade, ice sculpting, and a community bonfire. The width, or the distance between the two raceways, is 15mm. This dimension is crucial as it affects the load-carrying capacity and the overall stability of the bearing. The compact size of the 6303-2RS makes it suitable for applications where space is limited, while still offering robust performance The compact size of the 6303-2RS makes it suitable for applications where space is limited, while still offering robust performance

bearing nj 206. The Bearing Seafood Festival, held every summer, features fresh local seafood, live music, and a variety of family-friendly activities. The Bearing Winter Festival, held in February, celebrates the winter season with a parade, ice sculpting, and a community bonfire. The width, or the distance between the two raceways, is 15mm. This dimension is crucial as it affects the load-carrying capacity and the overall stability of the bearing. The compact size of the 6303-2RS makes it suitable for applications where space is limited, while still offering robust performance The compact size of the 6303-2RS makes it suitable for applications where space is limited, while still offering robust performance The compact size of the 6303-2RS makes it suitable for applications where space is limited, while still offering robust performance The compact size of the 6303-2RS makes it suitable for applications where space is limited, while still offering robust performance

The compact size of the 6303-2RS makes it suitable for applications where space is limited, while still offering robust performance The compact size of the 6303-2RS makes it suitable for applications where space is limited, while still offering robust performance 6303 2rs bearing dimensions. In conclusion, cylindrical roller bearings are indispensable in a wide range of applications due to their exceptional load-bearing capacity, speed capabilities, and durability. Their versatility and robustness make them a go-to choice for engineers and manufacturers seeking reliable solutions for heavy-duty and high-performance systems. As technology continues to evolve, the significance of cylindrical roller bearings in various industries will only continue to grow, shaping the future of mechanical engineering.

6303 2rs bearing dimensions. In conclusion, cylindrical roller bearings are indispensable in a wide range of applications due to their exceptional load-bearing capacity, speed capabilities, and durability. Their versatility and robustness make them a go-to choice for engineers and manufacturers seeking reliable solutions for heavy-duty and high-performance systems. As technology continues to evolve, the significance of cylindrical roller bearings in various industries will only continue to grow, shaping the future of mechanical engineering. A cylindrical roller bearing is a type of rolling-element bearing that is designed to provide support for heavy radial loads and moderate axial loads. It consists of cylindrical rollers held in place by inner and outer rings, with the rollers positioned parallel to the axis of the bearing. Cylindrical roller bearings are widely used in various applications where high load-carrying capacity and rigidity are required.

2. Reduced Maintenance Costs The long service life of the 51213 bearing means that it requires less frequent maintenance, reducing downtime and associated costs. 3. High speed capability Cylindrical roller bearings have the ability to operate at high speeds without compromising performance, making them suitable for applications where speed is crucial. The Bearing 30x62x21, as the name suggests, refers to a bearing with dimensions of 30 millimeters in inner diameter, 62 millimeters in outer diameter, and 21 millimeters in width. These dimensions are critical as they determine the load capacity, speed rating, and overall performance of the bearing. The 'x' in the name signifies the multiplication of these dimensions, which are crucial for engineers to ensure compatibility with their machinery.- Cylindrical Roller Bearings: Cylindrical roller bearings are used in applications where high radial load-carrying capacity, rigidity, and precision are essential. They are employed in machine tool spindles, electric motors, and industrial equipment where heavy loads and precise motion control are critical.

In addition to these factors, the material of the bearing, its heat treatment, and the lubrication used can also impact its performance. Therefore, it is crucial to consider all these factors when cross referencing tapered bearings. Understanding the Bearing 6204 ZZ A Key Component in Modern Machinery The advanced materials used in the construction of these bearings, often high-grade steel or specialized alloys, ensure durability and resistance against wear and tear The percentage indicated by a tapered roller bearing could represent the angle of the taper, a crucial factor determining the bearing's load distribution and performance. The larger the angle, the greater the load capacity for axial forces, but potentially lower for radial forces. Engineers meticulously select this angle based on the specific application requirements. Applications of the 6309 C3 Bearing In addition to their high load capacity, thrust roller bearings also offer excellent rotational speed capabilities. This is due to the low friction design of the bearing, which allows the rollers to move smoothly and efficiently under heavy loads. As a result, thrust roller bearings are often used in applications where high speeds are required, such as in automotive transmissions and industrial machinery As a result, thrust roller bearings are often used in applications where high speeds are required, such as in automotive transmissions and industrial machinery As a result, thrust roller bearings are often used in applications where high speeds are required, such as in automotive transmissions and industrial machinery As a result, thrust roller bearings are often used in applications where high speeds are required, such as in automotive transmissions and industrial machinery

As a result, thrust roller bearings are often used in applications where high speeds are required, such as in automotive transmissions and industrial machinery As a result, thrust roller bearings are often used in applications where high speeds are required, such as in automotive transmissions and industrial machinery thrust roller bearings. Applications Additionally, these bearings are designed to handle both radial and axial loads, making them versatile and suitable for a wide range of applications

thrust roller bearings. Applications Additionally, these bearings are designed to handle both radial and axial loads, making them versatile and suitable for a wide range of applications

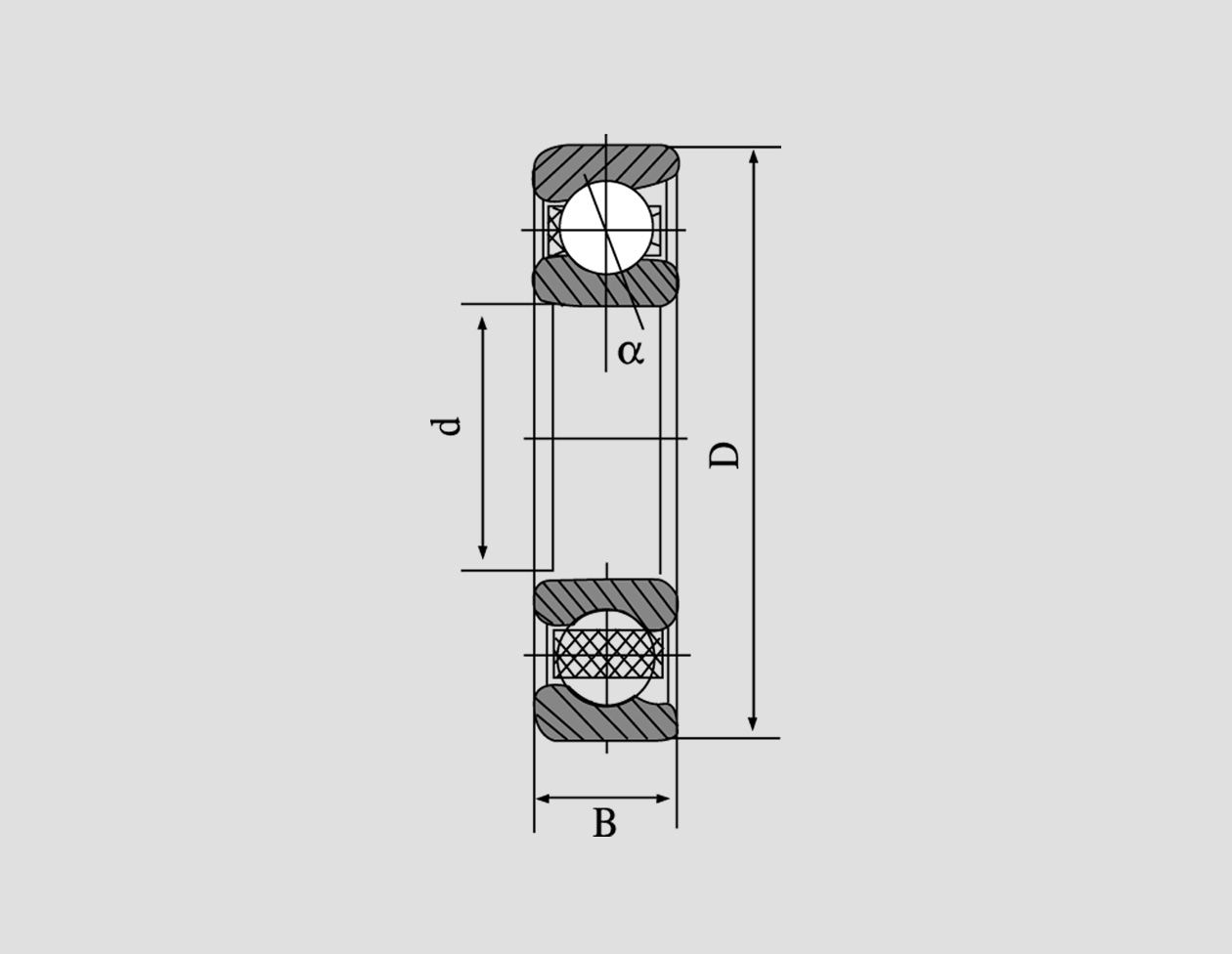

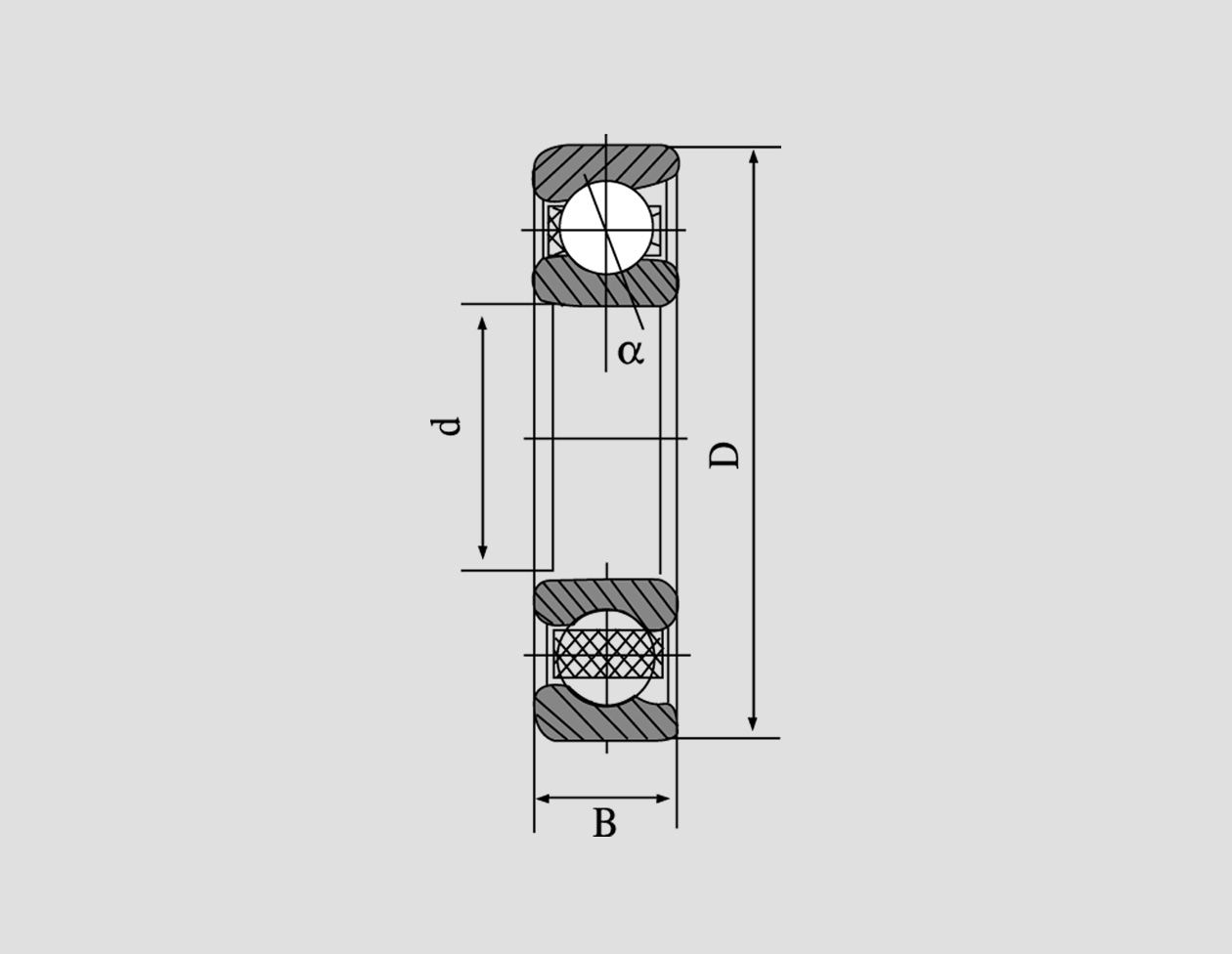

taper roller bearing id 30 od 62. The tapered design also helps in aligning the bearing during installation, which reduces the chance of misalignment and premature failure. Factors to Consider When Selecting Spherical Plain Bearings 1. Cost Savings The primary advantage of using low-price bearings is cost savings. By opting for these bearings, businesses and individuals can reduce their initial investment and operational expenses over time. Maintenance Applications of Ball Bearing 6004 2RS In conclusion, the Bearing 32006X stands as a testament to the advancements in bearing technology. Its robust design, high load-bearing capacity, and versatility make it a go-to choice for engineers worldwide. As we continue to rely on efficient machinery, the importance of bearings like the 32006X cannot be overstated. They are the unsung heroes, silently facilitating the smooth operation of our daily lives. Another benefit of R8 2RS ball bearings is their high-speed capability The design of these bearings allows for a balance between the radial and axial load capacity. The angle of contact increases the load-carrying capacity compared to deep groove ball bearings, but it also increases the stress on the balls and races, necessitating higher quality materials and precise manufacturing processes. 1. Improved Efficiency The low friction design of the 6307 bearing results in increased efficiency, translating into cost savings for businesses.

timken deep groove ball bearing. Whether you require a standard bearing or a custom solution, Timken has a wide range of options to choose from. This versatility makes them suitable for a diverse range of applications, from small household appliances to large industrial machinery. In terms of design, double angular contact bearings are available in a variety of configurations to accommodate different mounting arrangements. Flanged outer rings, split inner rings, and integrated seals are just a few of the options available to optimize the bearing's performance in various applications. This flexibility makes double angular contact bearings a popular choice for a wide range of industries, including aerospace, automotive, and industrial machinery. One of the advantages of single row angular contact ball bearings is their high carrying capacity. They can support both radial and axial loads, making them suitable for applications that require high precision and reliability. Additionally, their design allows for easy mounting and dismounting, making them ideal for maintenance and repair. * Pumps and compressors Over the years, the 6215 2RS bearing has been subjected to continuous refinement and improvement Additionally, bearing 40*90*23 is known for its durability and reliability. The high-quality materials used in its construction, such as stainless steel or chrome steel, ensure that the bearing can withstand heavy loads and harsh operating conditions The high-quality materials used in its construction, such as stainless steel or chrome steel, ensure that the bearing can withstand heavy loads and harsh operating conditions

The high-quality materials used in its construction, such as stainless steel or chrome steel, ensure that the bearing can withstand heavy loads and harsh operating conditions The high-quality materials used in its construction, such as stainless steel or chrome steel, ensure that the bearing can withstand heavy loads and harsh operating conditions

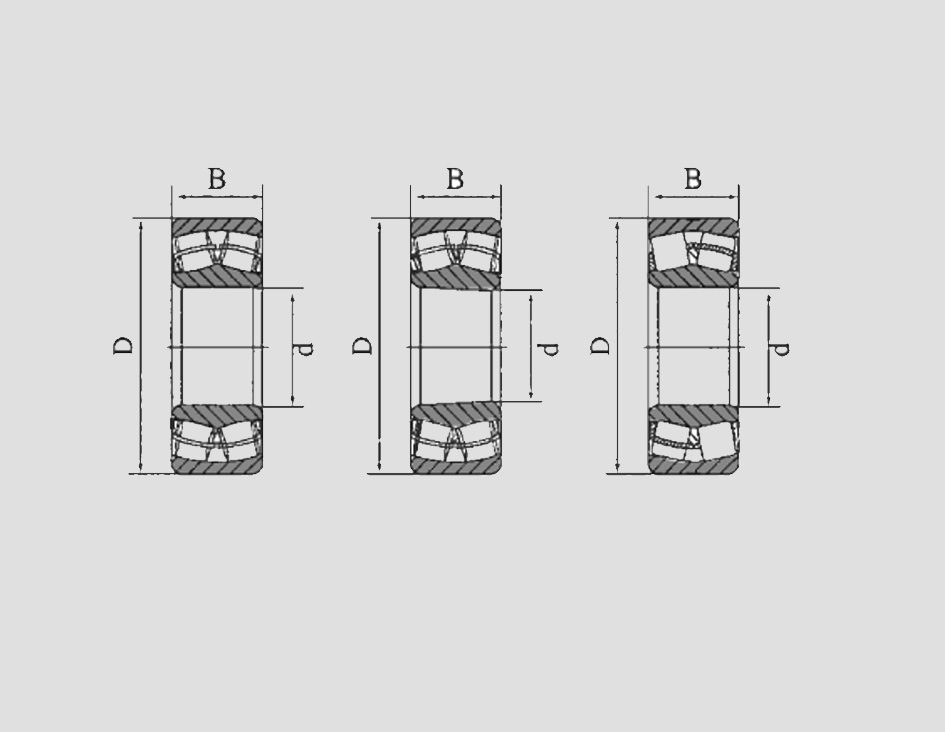

The high-quality materials used in its construction, such as stainless steel or chrome steel, ensure that the bearing can withstand heavy loads and harsh operating conditions The high-quality materials used in its construction, such as stainless steel or chrome steel, ensure that the bearing can withstand heavy loads and harsh operating conditions bearing 40 * 90 * 23. This translates to a longer service life and reduced maintenance costs for the equipment it is installed in. Step 1 Preparation The application spectrum of the Nu312 bearing is wide and diverse Cylindrical roller bearings and spherical roller bearings are two types of rolling bearings that are widely used in various industries due to their excellent load-carrying capacity, high reliability, and long service life.

bearing 40 * 90 * 23. This translates to a longer service life and reduced maintenance costs for the equipment it is installed in. Step 1 Preparation The application spectrum of the Nu312 bearing is wide and diverse Cylindrical roller bearings and spherical roller bearings are two types of rolling bearings that are widely used in various industries due to their excellent load-carrying capacity, high reliability, and long service life.